Road panels are the ideal solution for temporary purpose-built roads, detour routes and temporary areas for parking, storage and other applications. They are designed to provide an efficient and quick way to create temporary infrastructures, especially where quick set-up is needed without loss of quality. Road panels can be created from different materials such as concrete or plastic, but concrete road panels are most commonly used in practice.

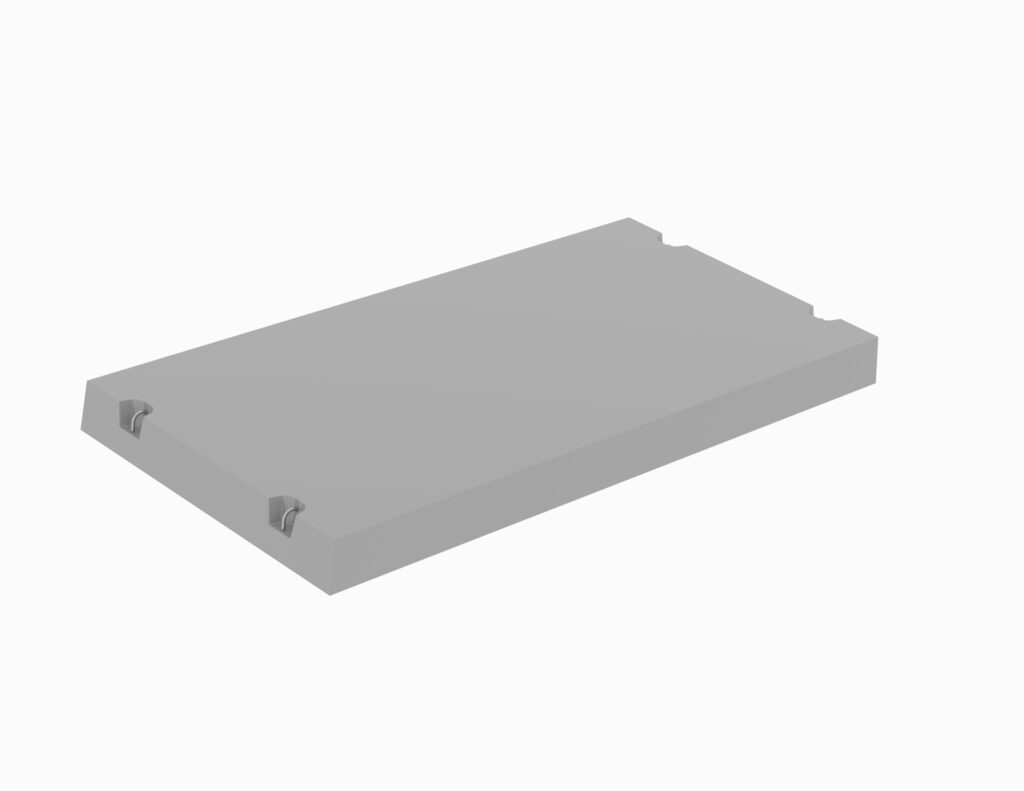

Concrete road panels offer easy and demountable assembly of road surfaces. The technical parameters, dimensions and load of these panels ensure that they are able to withstand heavy traffic loads and at the same time be easy to handle during installation and dismantling. Thanks to the thickness of the panels, they can be suitable for driving heavy cars up to a total weight of 20 tons.

When designing and planning road panels, it is important to consider their lifespan, which is designed with the assumption of a five-year lifespan. Manufacturers and construction professionals must ensure that technical standards and parameters are strictly followed during the construction of road panels to ensure their safety and functionality.

Basic characteristics of road panels

Road panels are structural elements used mainly for the creation of temporary purpose-built roads, bypass routes, parking, warehouse and other paved areas, but also permanent roads III. and IV. classes. They are designed to provide an efficient and quick opportunity to create the necessary infrastructures. In the following paragraphs, you will learn more about the material, reinforcement, dimensions and load capacity of these panels.

Material and reinforcement

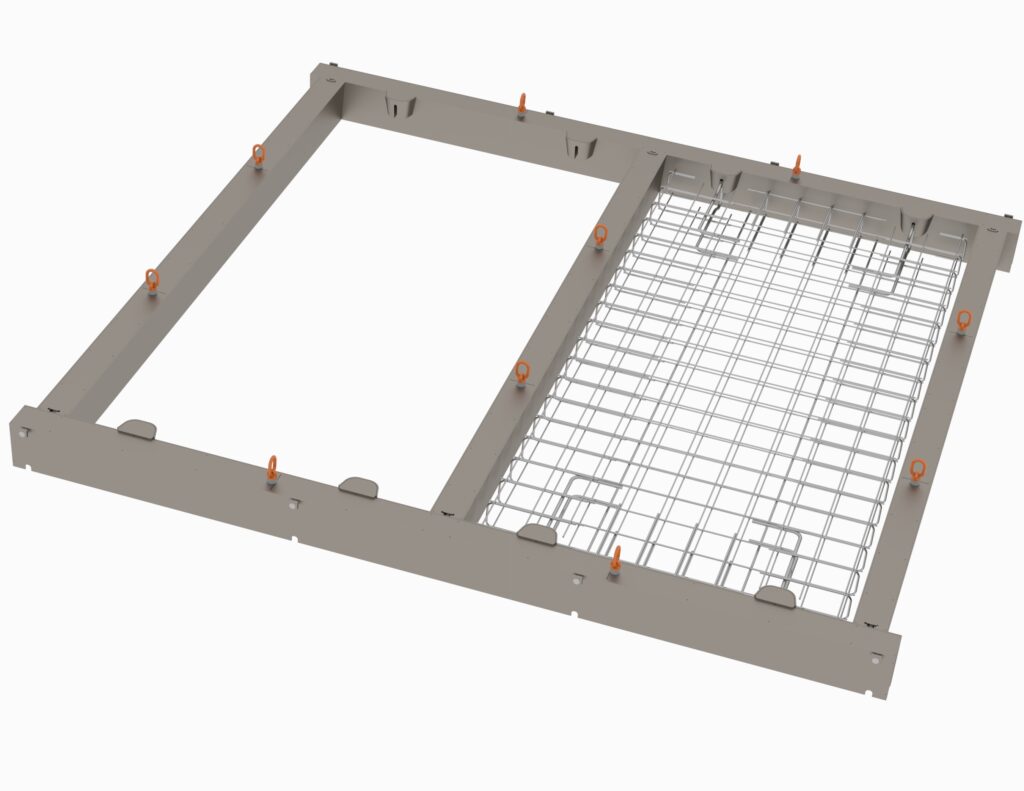

Road panels are made of reinforced concrete. This material is a combination of concrete and steel reinforcement, which increases the load-bearing capacity and durability of the panels. This makes them an ideal solution for various types of traffic loads, from passenger vehicles to freight transport.

Size and weight

The dimensions and weight of road panels vary according to type and use, but the basic dimensions are in length 3000 mm and width 1000, 1500 and 2000 mm. The thickness of the road panel is an important parameter that determines its load capacity. Panels with thicknesses are commonly produced 150, 180 and 215 mm.

The load capacity of the road panel depends on its thickness:

- Thickness panels 150 mm are intended for vehicles up to total weight of 6 tons with maximum tire pressure 21 kN.

- Thickness panels 180 mm are also intended for vehicles up to total weight of 6 tons, but with a lower maximum tire pressure.

- Thickness panels 215 mm are intended for trucks up to total weight of 20 tons with maximum tire pressure 50 kN.

The basic parameters of road panels are clearly summarized in the following table:

| Thickness | Width (mm) | Length (mm) | Load capacity (tons) | Max. wheel pressure (kN) |

|---|---|---|---|---|

| 150 mm | 1000/1500/2000 | 3000 | 6 | 21 |

| 180 mm | 1000/1500/2000 | 3000 | 6 | – |

| 215 mm | 1000/1500/2000 | 3000 | 20 | 50 |

Laying

Laying

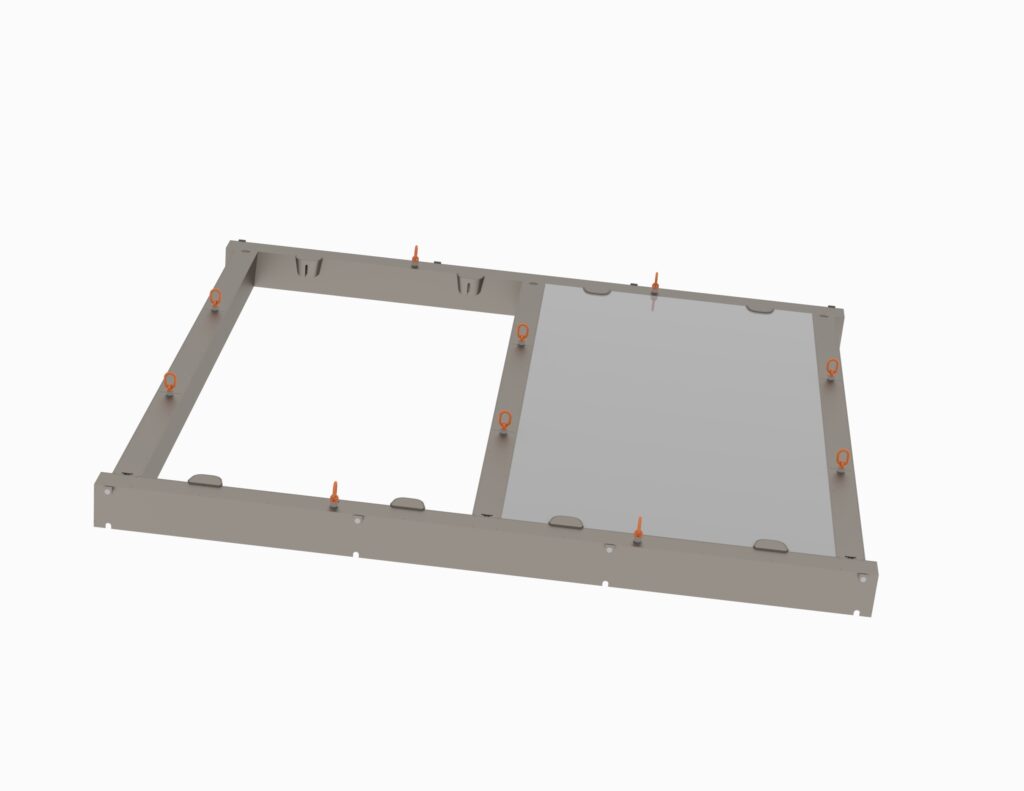

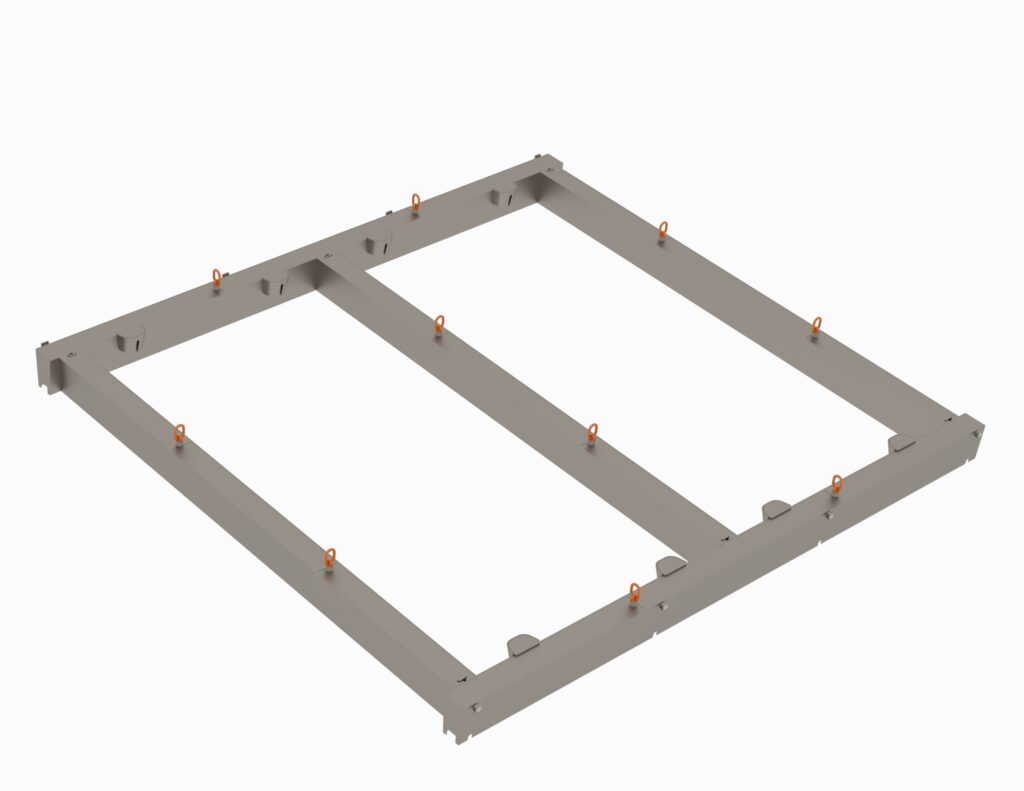

Installation of road panels is simple and efficient, thanks to their modular nature and quick handling. First you need to prepare gravel subsoil, which must be straight and compacted, with a minimum gap of 10 mm between individual elements. Handling of panel elements is done in use cranes, which ensure the correct position and arrangement of the panels on the substrate.

- Preparation of gravel substrate

- Topsoil cover

- Installation of panels using cranes

Conditions for laying

Regarding the conditions for the assembly and disassembly of road panels, the following criteria must be observed:

- Before preparing the gravel substrate, it is necessary carry out topsoil stripping.

- The minimum bearing capacity of the soil under the gravel subgrade should be Rdt = 150 kPa.

- In the event that the panel structure needs to be relocated or dismantled, it is crucial to ensure careful storage and manipulation of individual panel elements.

The quick assembly and disassembly of road panels is a great advantage in connection with the use of these structural systems for temporary or portable projects, such as temporary purpose-built roads or temporary detours.

Use and application of road panels

Temporary and permanent communications

Road panels are the ideal solution for temporary communication, such as construction roads, detours or temporary roads. Thanks to quick and easy assembly and disassembly, the panels are suitable for situations where a temporary infrastructure needs to be quickly established. In addition, IZD road panels can also be used for permanent roads III. and IV. classes.

These are flat reinforced concrete elements of rectangular format with different dimensions and parameters. Thanks high bearing capacityand durability, these panels withstand various weights and cause minimal loss of surface quality.

Industrial and storage areas

In addition to temporary and permanent roads, road panels are also used for industrial and storage areas, where high load-bearing capacity is required for transport and automobiles. These panels are suitable for creating paved parking and industrial areas with good utility properties.

They are not used for special roads, but are ideal for repeated use. Easy manipulation and moving of the panels to another location allows the areas to be effectively expanded or reduced as needed.

Get to know some of the key features of road panels:

- High load capacity and resistance

- Various dimensions and parameters

- Quick assembly and disassembly

- Ideal for repeated use

- Minimal loss of surface quality

Road panels provide an efficient and fast solution for temporary and permanent connections and surfaces, covering many possible uses in transport and industry.

Advantages

Efficiency and economy

Road panels offer an effective solution for various purpose-built roads. These panels are capable of carrying a load of up to 20 tons, which ensures their use in a wide range of applications. The material from which they are made provides considerable durability and resistance. Due to the simple installation, the road panels can be quickly placed in the desired location, which not only saves time, but also reduces the cost of labor and materials.

The financial benefits of road panels also come from being able to be reused if needed. This sustainability brings economic benefits and increased investment value. In addition, the cost of installation and operation of these panels can vary depending on the material, but compared to traditional construction methods, they usually bring savings.

Durability and maintenance

Road panels show positive characteristics in terms of durability and maintenance. The resistance of the materials to various conditions is a plus, however, the nuances take into account the differences between the materials and their maintenance requirements. For example, izd is a material that is resistant to some weather conditions, but may require regular maintenance.

Another key factor that affects the durability and maintenance of road panels is the price. Differences in the prices of individual materials can have an impact on the choice, but the decisive factor should be the trade-off between quality and price. It is advantageous to choose a material that provides longer durability and lower maintenance requirements.

Last but not least, we should take into account the directives or laws regulating the use of individual materials and they are established with the aim of guaranteeing safety, durability and an ecological approach. Therefore, when choosing road panels for a given project, it is necessary to pay attention to the regulations and guidelines valid for the given territory.

Technical specifications and standards

Load category

Road panels are designed for different load categories, which depend on the type of vehicles and axle pressure. The load capacity of the panels is usually divided into two basic load capacities: for loads of 6 tons and 20 tons.

- Load 6 tons: This category includes light vehicles and is suitable for temporary parking lots, purpose-built roads or pedestrian areas.

- Load 20 tons: This category is intended for heavy vehicles such as trucks or construction machinery. In this case, the road panels are designed to withstand the load on roads III. and IV. classes.

Panels made of reinforced concrete have sufficient resistance to loads from heavy vehicles. Different grades of reinforcement and concrete are used, usually C 30/37 – XC4, XF1 and steel B 10505.

Factions and Subsoil

Fraction and subsoil are other important elements that affect the technical properties and service life of road panels. The basis of the concrete used is a cement matrix, filler (aggregate) and water. Modifiers are added to improve concrete properties and wear resistance.

The panels are easily assembled and, if necessary, dismantled, which allows them to be used repeatedly. During installation, it is important to ensure that the substrate is stable and evenly distributed, which will ensure optimal performance and long-term longevity of the panels.

Companies such as MABA Prefa or HB Beton produce road panels according to customer specifications, which include shape and dimensions, concrete grade and reinforcement. However, the basic standards and technical data that serve as the basis for the manufacturers' technical sheets still apply.

FAQs

What are the standard dimensions of concrete road panels?

Road panels have different standard dimensions, but are commonly produced in heights of 150, 180 and 220 mm. It is important to note that the specific dimensions may depend on the manufacturers and the use of the panels.

What is the difference between the different types of road panels available in the market?

Different types of road panels differ in materials, dimensions and purpose of use. Some panels are intended for temporary purpose-built roads, parking, warehouses and other paved areas, while others may be suitable for permanent roads. It is always advisable to consult technical sheets and requirements for a specific project.

What is the approximate price for a 2x3 meter concrete panel?

The price of road panels can vary depending on the manufacturer, material and dimensions. We recommend contacting the manufacturer for an exact price quote.

Is it possible to purchase road panels with special dimensions to order?

Yes, some manufacturers offer the possibility of creating road panels with atypical dimensions to order. However, it is important to note that custom dimensions may have limitations and may increase costs.

Where can you find used road panels and what is important to consider when buying them?

Used road panels can be found on internet sales platforms or through specialist companies. When buying, it is important to check the condition of the panels, their dimensions and material, so that they are suitable for a specific project.